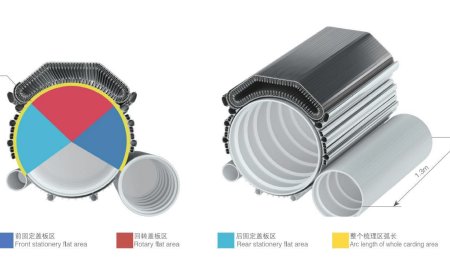

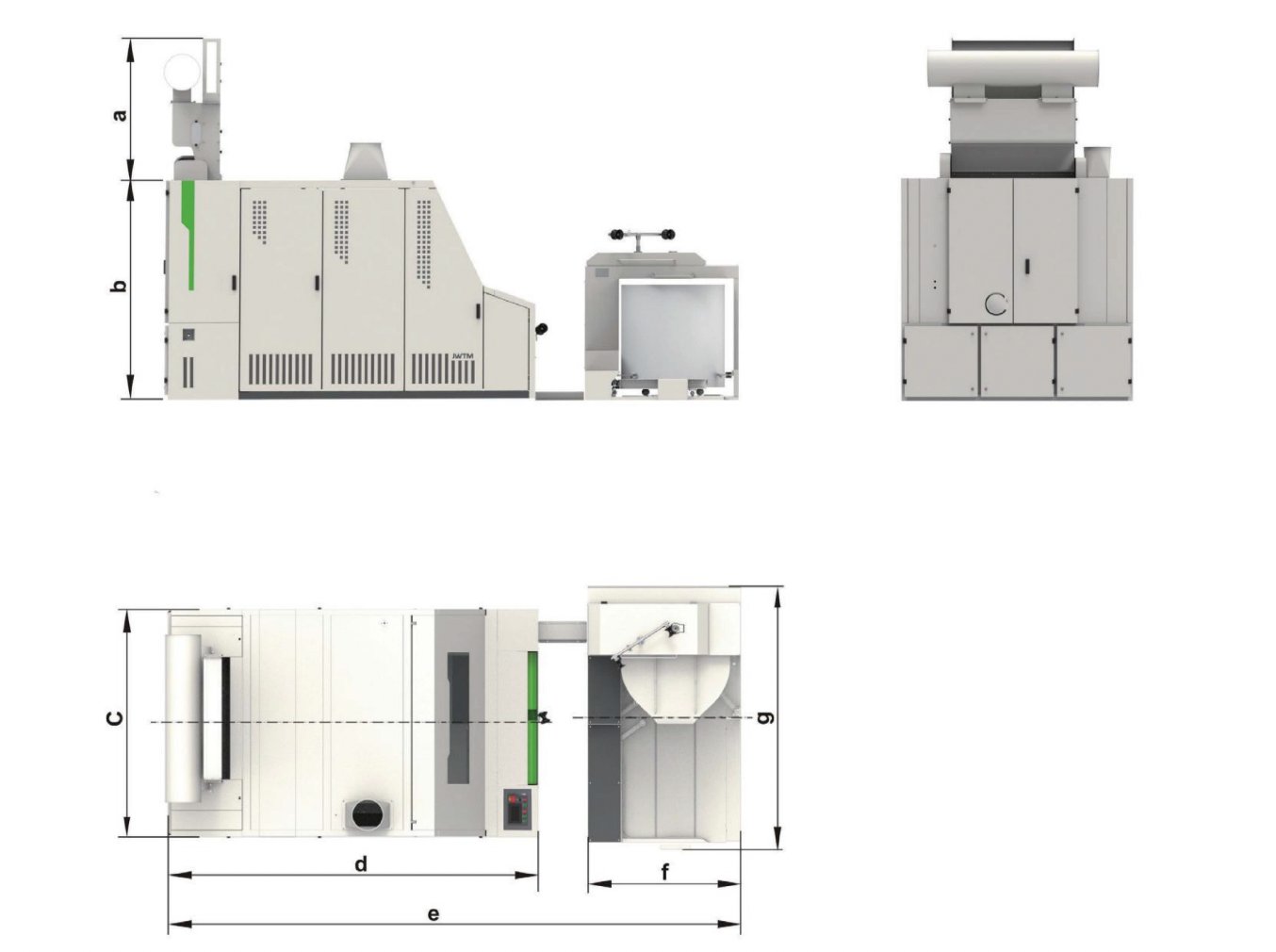

CARDING SYSTEM WITH HIGH PRODUCTION AAND EFFICIENCY

STABLE AND RELIABLE QUALITY GUARANTEEE

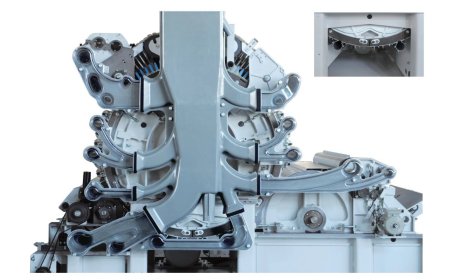

NEW TYPE OF LICKER-IN CARDING SYSTEM

DUST FILTERING SYSTEM

MODULAR DESIGN-EASY OPERATION AND MAINTENANCE

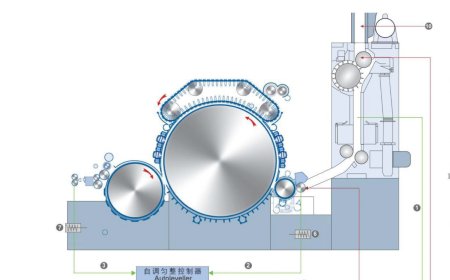

NEW TYPE MIXED LOOP AUTO-LEVELLER SYSTEM

NEW TYPE DETECTING AND PROTECTING :SYSTEM

SLIVER CUTTING WITHOUT SPEED DOWN

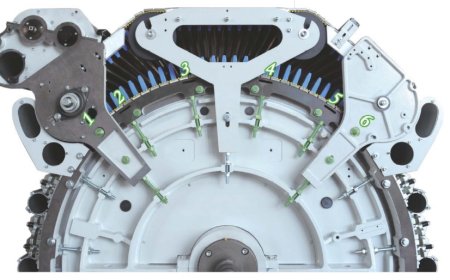

DISTINCTIVE 6-POINTS GAUGE

TYPE OF CHUTE FEEDER

LANGUAGE

LANGUAGE