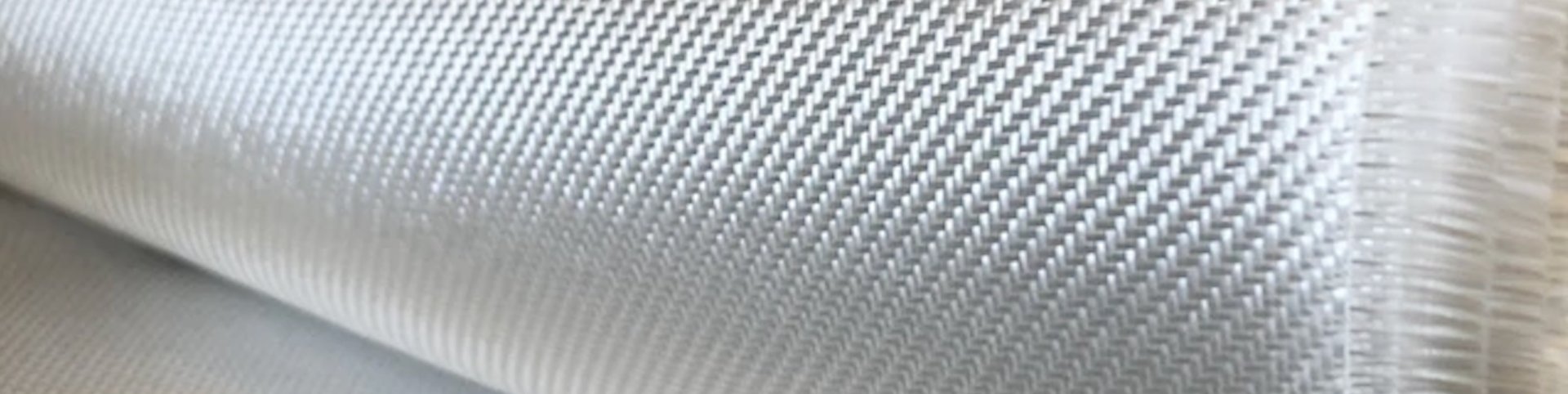

The Fiberglass Air Jet Loom TDA-810 boasts high reliability due to its touchscreen with new communication technology and innovative electromechanical design. The new integrated side frames and balanced weft insertion system work together seamlessly, catering to various yarn counts and ensuring high-speed, low-vibration weaving with superior quality. The user-friendly design, including an external warp device and intuitive interface, makes the machine more operator-friendly. Additionally, the new energy-saving weft insertion system shortens air paths, increases jet sensitivity, and reduces air consumption.

LANGUAGE

LANGUAGE