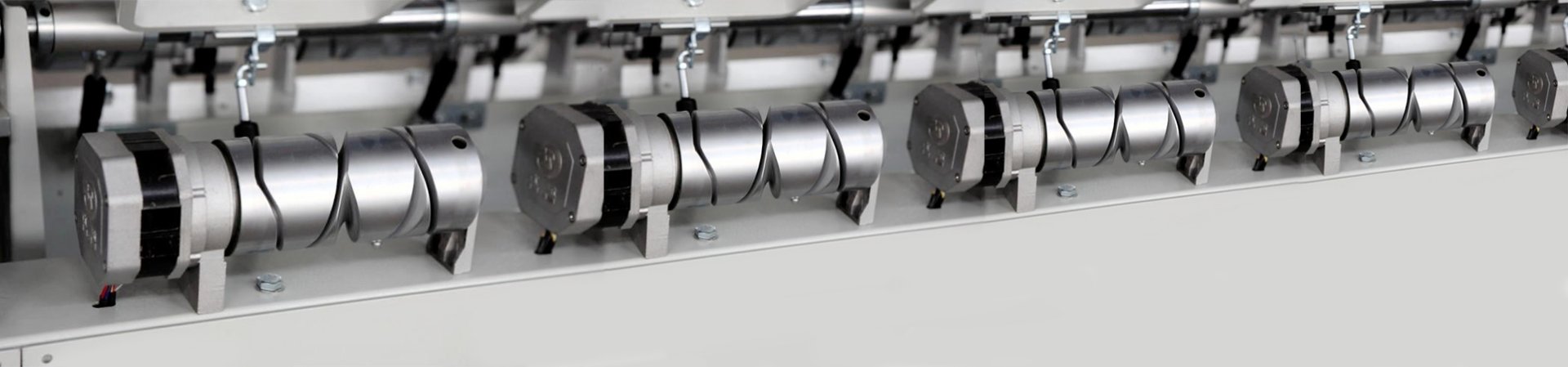

The Ni-P Alloy Grooved Drum undergoes a modified groove curve process, achieving an ultra-fine finish with a mirror polished surface (Ra<0.2μm). The Ni-P plating has a high density, small crystallization, and low porosity. The grooved drum coating is uniformly applied and offers excellent corrosion resistance. The Ni-P alloy coating undergoes aging, hardening, and high-temperature heat treatment, reaching a surface hardness of HV1100. This provides advantages such as high wear resistance, high toughness, and low internal stress. The product offers better wear resistance, corrosion resistance, uniformity, and a longer lifespan.

LANGUAGE

LANGUAGE