Tongda MK8 Carding Machine Production Base

MK8 Carding Machine

1.Carding system with high production and efficiency

Mono-block casting iron cylinder, doffer and side wall ensures good stability and low thermal expansion coefficient. The carding technical gauge is stable even when machine runs at high speed, ensuring the high production.

The stepped entity frame welded by steel plate is characterized by its flexible mechanism and its special processing technology, ensuring the major gauge stable and uniform.

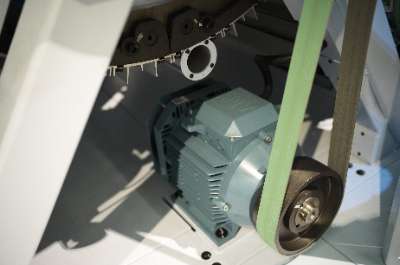

2.New type of driving method

Cylinder and licker-in adopt high torque motor, featured by stable start and reliable rotary.

Doffer is driven by inverter motor to ensure stability in low speed, high speed and speed conversion.

- Flat is driven by independent inverter motor for convenient speed adjustment.

3.Cleaning unit with high efficiency

The gauge adjustable design of the brush roller and the revolving flats ensures the deep cleaning of the revolving flats.

The optimized relative position and gauges between the brush roller and cleaning roller ensures the timely removed of the flat cotton fly.

The new type of aluminum suction hood with perfect fluid mechanics can reduce the drag and suck flat fly smoothly.

4.New type of licker-in carding system

Licker-in is designed with two noil area whose length is adjustable outside of machine.

It is designed with two sets of mote knife, pre-carding segment for efficiently removal of trash and staple.

Noil area length is adjusted flexibly according to quality, type of material.

Arc length of the first noil area is adjusted freely around licker-in center.

Angle of tongue plate in the second noil area is adjusted according to requirement.

5.Stable air suction and airflow gurantee the carding qualtly

The new dust-filtering system adopts the streamline structure and is more in line with the flow kinematics, which can reduce wind resistance as well as save energy and reduce cost.

Aluminum-alloy enclosed undercase, easy dismantling,better controlling of air flow, beautiful profile.

6.Modular design-easy operation and maintenance

Aluminum alloy rotary flat bar is made by special material,with the characteristics of good flatness, light weight, stable operation.

It is guided by two tooth belts without need of other fasten parts, so it is easy for mantle, dismantle and maintenance.

Duplex stationery flats, web cleaners and cover plates adopt aluminum alloy material. The fine needle flatness and easily adjustable gauge guarantee the fine and intensive material carding.

Vodular design realizes flexible replacement to meet different technical requirements based on various material and guarantees excellent product.

( Read More : Ring Spinning : Definition, Process , Main Operations )

( Read More : How does rotor spinning work? Principle. Operation. Application)

LANGUAGE

LANGUAGE